- Total Maintenance

Ensure the OEE of Facilities of Manufacturing , Utilise with the help of Advance Maintenance management. - Total Restoration

Ensure the Restoration as original equipment to operate with their optimum capacity & Safety aspects. - Engineering & Consulting

Ensure to select the right facilities, which help production to achieve their target. - Installation & Commissioning

Ensure to Install & complete the Commissioning of equipment as per Manufacturer’s specified process.

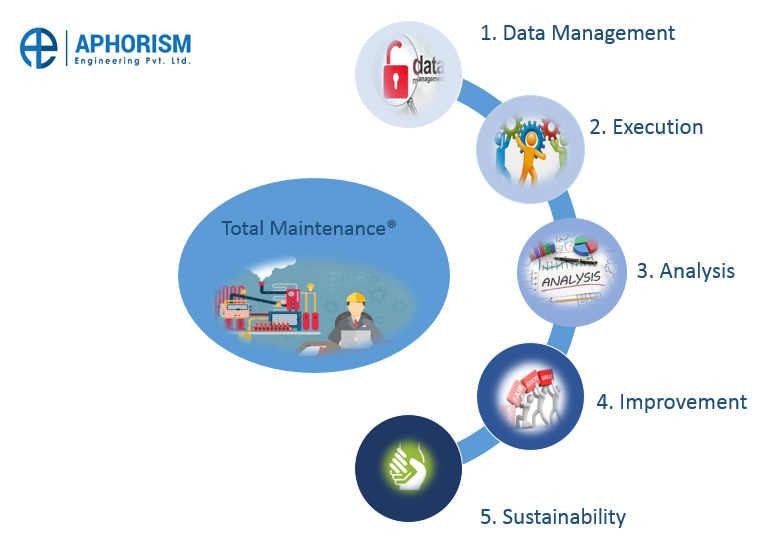

Total Maintenance

Service that improve the OEE of Assets by adding the Value of Reliable Monitoring.

Put our know-how and experience to work for you

At AEPL Total Maintenance, we know your plant inside out and from top to bottom – because we have a very reach experience to maintain & built such. Till date, we have Maintained Heavy Electrical Equipment manufacturing plants to the highest quality and safety standards. We bundle this proven engineering experience with the operational expertise of such Plant and multiply these insights with the latest intelligent, networked technologies. So you can look forward to analytical operational support, smart training and expert safety consulting. With a trusted, experienced partner at your side, you are free to concentrate on running your business.

Total Maintenance

We take full responsibility for maximising the potential of all aspects of maintenance, from management to organization and execution of all site activities for Pro active and preventive maintenance, as well as shut downs, upgrades and modifications. We take a holistic approach and commit to improving safety, productivity and energy efficiency while optimizing cost. Where relevant, our responsibility goes beyond maintenance to include the operation of plant utilities, for example Air, Power, and water treatment. We provide the CMMS for Plant Data management. Each & Every Activity executed under Customer Supervision.

Core Responsibilitie:

- Data Management by CMMS (Collection, Master Data creation / Updating , Routine Input data Updating , Monitoring, Analysis )

- Project Planning based on report of Predictive Maintenance, RBM, RCM, FMECA etc.

- Procurement Management. ( PR, PO, Store Management )

- Execution Maintenance Order i.e. BDM, PM, PDM etc. as per user equipment.

- Ensure Sustainability by continues improvement in Process.

- Man Power Management.

- Training for technician & Engineer.

- Customer is responsible to provide safe & heathy work atmosphere.

- Customer is also responsible to achieve the final goal or target by helping each & every source or resources in deadline provided by AEPL.

Total Maintenance except CMMS

We take full responsibility for maximising the potential of all aspects of maintenance, from management to organization and execution of all site activities for Pro active and preventive maintenance, as well as shut downs, upgrades and modifications. We take a holistic approach and commit to improving safety, productivity and energy efficiency while optimizing cost. Where relevant, our responsibility goes beyond maintenance to include the operation of plant utilities, for example Air, Power, and water treatment. Responsible to update the data in ERP system owned by Customer. Each & Every Activity executed under Customer Supervision.

Core Responsibilities:

- Data Management in Customer owned ERP system (Collection, Master Data creation / Updating , Routine Input. data Updating, Monitoring, Analysis )

- Project Planning based on report of Predictive Maintenance, RBM, RCM, FMECA etc.

- Procurement Management. ( PR, PO, Store Management )

- Execution Maintenance Order i.e. BDM, PM, PDM etc. as per user equipment.

- Ensure Sustainability by continues improvement in Process.

- Man Power Management.

- Training for technician & Engineer of AEPL.

- Customer is responsible to provide safe & heathy work atmosphere.

- Customer is also responsible to achieve the final goal or target by helping each & every source or resources in deadline provided by AEPL.

Maintenance Management

We take full responsibility for maximising the potential of all aspects of maintenance, from management to organization and execution planning of all activities for Pro active and preventive maintenance, as well as shut downs, upgrades and modifications. We take a holistic approach and commit to improving safety, productivity and energy efficiency while optimizing cost ( Management staff ). Each & Every Activity executed under Customer Supervision.

Core Responsibilities:

- Data Management in Customer owned ERP system (Collection, Master Data creation / Updating , Routine Input data Updating, Monitoring, Analysis )

- Project Planning based on report of Predictive Maintenance, RBM, RCM, FMECA etc.

- Procurement Management. ( PR, PO, Store Management )

- Execution Maintenance Order i.e. BDM, PM, PDM etc. as per user equipment.

- Ensure Sustainability by continues improvement in Process.

- Training for technician & Engineer of AEPL.

- Customer is responsible to provide safe & heathy work atmosphere.

- Customer is also responsible to achieve the final goal or target by helping each & every source or resources in deadline provided by AEPL.

Asset Class Maintenance

We take full responsibility for all aspects of maintenance for specific classes or families of equipment. This could include electric motors, EOT Carnes, drives, instrumentation, process automation and power distribution. As an OEM independent service provider, we work with all types and all manufacturers’ equipment to reduce downtime, improve performance, and extend equipment lifetime. Each & Every Activity executed under Customer Supervision.

Core Responsibilities:

- Data Management in Customer owned ERP system (Collection, Master Data creation / Updating , Routine Input data Updating, Monitoring, Analysis )

- Project Planning based on report of Predictive Maintenance, RBM, RCM, FMECA etc.

- Procurement Management. ( PR, PO, Store Management )

- Execution Maintenance Order i.e. BDM, PM, PDM etc. as per user equipment.

- Ensure Sustainability by continues improvement in Process.

- Man Power Management

- Training for technician & Engineer of AEPL apart from standard equipment.

- Customer is responsible to provide safe & heathy work atmosphere.

- Customer is also responsible to achieve the final goal or target by helping each & every source or resources in deadline provided by AEPL.

Maintenance Force Support with Consultation

We are responsible to provide the skilled Maintenance work force decided by your own management to achieve your business goal. Customer is fully responsible to run their maintenance without our any concern related to plant equipment. We Support our customer to identify the RCA & help them to do Macro and Micro analysis on Maintenance management trough out the tenure.

Core Responsibilities:

- Execution Maintenance Order i.e., BDM,PM,PDM etc. as per user equipment under Customer Real Time Supervision.

- Man Power Management

- Consultancy on Maintenance management.

- Customer is responsible to provide safe & heathy work atmosphere.

- Customer is also responsible to achieve the final goal or target by helping each & every source or resources in deadline provided by AEPL.

Maintenance Force Support

We are responsible to provide the skilled Maintenance work force decided by your own management to achieve your business goal. Customer is fully responsible to run their maintenance without our any concern related to plant equipment.

Core Responsibilities:

- Execution Maintenance Order i.e., BDM,PM,PDM etc. as per user equipment under Customer Real Time Supervision.

- Man Power Management

- Customer is responsible to provide safe & heathy work atmosphere.

- Customer is also responsible to achieve the final goal or target by helping each & every source or resources in deadline provided by AEPL.

we have been realizing the full potential of maintenance for our customers. From embedding superior safety practices and building a true maintenance culture, to optimizing maintenance cost and improving plant performance, our people make the difference. We are passionate about maintenance and proud of ensuring we achieve our customers’ goals in the most professional way.

Maintenance is more than just a cost to production. It provides the foundation for a business’s performance and portability, a‑acting everything from safety to plant productivity and energy efficiency.

From designing a new plant, to getting it running and keeping it running optimally, having the right approach to maintenance makes a real difference in both the short and long-term. However, the full potential of maintenance is rarely realized. When working with new customers we often find: the total cost of maintenance is not under full control; spare parts and subcontracting costs constantly exceed budgeted levels; the impact of maintenance on the equipment life cycle cannot be qualified; maintenance is conducted in isolation of productivity improvements; and the cost of unplanned shut downs is greater than the total planned maintenance budget. In a world where increasing regulation, competition and costs put pressure on our customers’ businesses, we constantly ask: Where can maintenance have the greatest impact; how can it contribute to a more prosperous future for our customers, in both the short and long-term?

All customers are concerned about rising maintenance costs and many need to improve safety performance. Some want to increase productivity or capacity to seize market opportunities. Others need to improve energy efficiency to reduce operating costs or reduce waste to meet regulatory changes.

When our customers outsource their maintenance management and execution to us we ensure that they achieve both their short and long-term goals. We deploy empowered, maintenance-focused people to work as an integrated part of their production teams, using world-class processes and methodologies to improve safety and productivity all while optimizing cost.

To meet our customers’ goals, we have a proven process for evaluating the potential we can realize before we start working together. Agreed goals are then continuously reviewed against actual performance. Working under performance-based agreements helps ensure that all investments in maintenance create ‘real’, sustainable business benefits, and that we all share in the value created. Our unique approach to optimizing maintenance management and execution, with a focus on education, motivation and empowerment, takes our customers’ performance to the next level adding value in both the short and long-term.

Sustainability

Sustainability is considered in all that we do; how we design our services, what we offer customers, how we engage suppliers, how we assess risks and opportunities, and how we behave in the communities where we operate and towards one another.

In AEPL, Occupational Health and Safety, Environment, Quality and Integrity are all contributing to sustainability.

Benefits getting by selecting AEPL Total Maintenance

| Improved | Reduced |

|---|---|

| Safety Performance | Safety Incidents |

| Employee Motivation | Operating Cost |

| Energy Efficiency | Maintenance Cost |

| Overall Equipment Effectiveness | Spare Parts Cost |

| Equipment Lifetime | Energy Consumption |

| Equipment Availability | Production Losses |

| Equipment Reliability | Downtime |

| Maintenance Productivity | Emissions |

| Compliance | Waste |