Safety Light Curtain

Safety and profitability – that is what many manufacturers promise. However, we are the only one, who can offer one product featuring this variety of integrated functions without external tools.

- Automatic and restart interlock mode

- EDM contactor control

- Double acknowledgement/reset

- Stationary and dynamic object blanking

- Blanking with movable edge region

- Beam coding

- Status and diagnostic indication

- Integrated set-up tool

- Multiple sampling

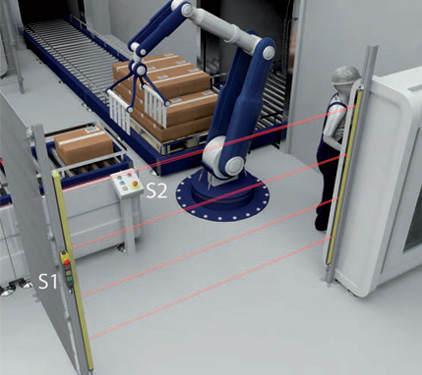

- Muting

- Cyclic operation

Large production areas which are only partly visible, present multiple risks which include persons walking behind the safety equipment, or third parties pushing the acknowledgment button thereby inadvertently restarting of the machine.

The solution: the SLC/SLG 440-445 integrates the function “Double acknowledgment”. The additional input is integrated in the receiver.

As soon as anyone enters the hazardous area the hazardous movement is stopped. The safe release is then carried out.

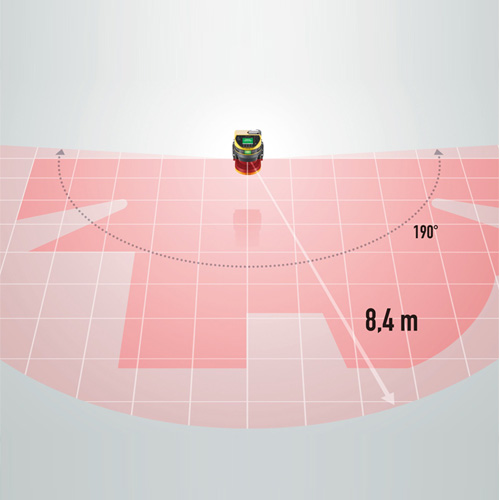

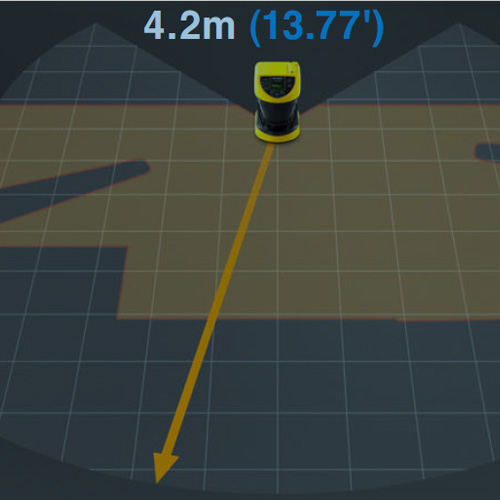

Safety Laser Scanner

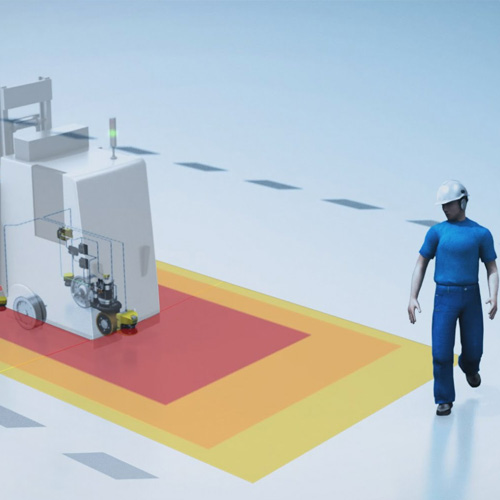

A safety laser scanner can be mounted on an automated guide vehicle. The following three area settings are available: Slow Area, Stop Area and Emergency Stop Area. SZ-16V users can configure up to 16 different zone, stop, and emergency stop area settings for a total of 48 ones.

- Non-contact detection is free from damage caused by falling objects or vehicle traffic

- No need to stock different size mats

- Protection zones easily modified for workspace layout changes

- Easy to move due to its compact body and light weight

- Complex-shaped zones can configured

Safety Mate

- Robust design

- Modular switching mat system

- Special sizes are available on request

- Maintenance free

- Simple mounting

- Slip-free surface

- High resistance to chemicals

- No additional terminating resistor required

- No additional baseplate

- 4-wire connecting cable

Safety Flap

Non-Contact Type Switch

Safety Fence

Machine Guarding Activities

APHORISM is the leading machinery guarding specialist, offering a comprehensive service to survey, design, manufacture and install machine guards nationwide, whether the requirement is for close-fitting guards, perimeter guards or a combination of both. With unrivalled knowledge of the applicable standards, as well as a deep understanding of the ergonomic issues relating to machine guarding, Aphorism can design guards that meet all the necessary safety standards, do not hinder production, and enhance the machine’s aesthetics.

Guarding Application

APHORISM guarding has facility to make customized. It will be designed on CAD software. The design will give the idea about selection and Hazard mitigation, even it helps in assembly.

The APHORISM guarding is easy to install, light in weight.

Sliding Door, Leaf Door and Window

APHORISM guarding has special designed accessories to arrange the door as per the application requirement.

The door is supplied with ergonomic Handle, pair of hinges, Magnetic Locking System.

Smoothly operated Sliders. The Door Assembly design is Easy to align with safety Switch. Standard bracket will be provided for mounting of interlocking switches.

Software Design

The dedicated design team generates the guarding layout in 2D as well 3D. Based on the application requirement the layout will be generated. The Software design allows dialog with the customer without need of file conversation.

The design data will provide the complete Bill of Material which helps in ordering to customer. It avoids the misinterpretation of the positioning of the protection equipment. The installers work from an isometric drawing which avoids any possible confusion as to positioning of the protection components and equipment.

Execution Plan

APHORISM has the dedicated team for installation. Based on the CAD drawing the team will mark the site location utilize for guarding. This preparation gives better idea for installation and even assure that the space is ready for the installation. Also, the indirect owners of the location will aware about the guarding. As the trained person will do the activity the project executes in proper working manner in less time which helps to users in terms for less amount of shut down time.

Machine Guarding Directives

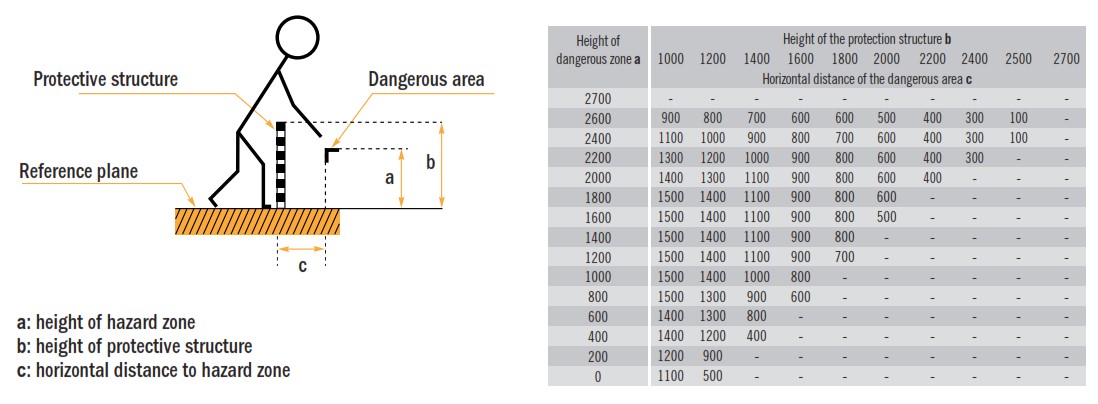

The standard EN ISO 13857 gives guidance on the safety distances for fencing systems and other fixed protective structures.

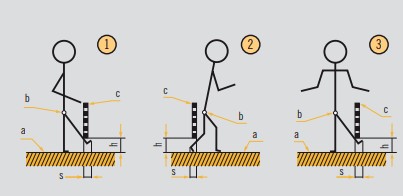

EN ISO 13857, 4.2.2: Reaching Over Protective Structure:

EN ISO 13857, APPENDIX B

The below pictures 1,2 and 3 report the distance S for particular cases where the access of the lower limbs of a person in a standing position is impeded without supplementary measures. If the height h up to the bottom of the guard ranges between two values, the distance indicated for the higher h value should be use.

If the danger area at the low risk, the height of the h of this area shall be ≥ 2500 mm. If the dangerous area is at high risk, the height h of the dangerous area shall be ≥ 2700 mm or further safety measures shall be adopted.